In large-scale industrial piping systems where operating conditions demand strength, thermal stability, and long-term reliability, ASTM A182 F22 Flanges continue to be a preferred choice. From refinery process lines to high-pressure steam systems in power plants, these flanges support critical operations across global markets. For international industrial buyers and EPC contractors, ASTM A182 F22 flanges offer a proven combination of metallurgical performance, global standards compliance, and dependable export supply.

Defining Alloy Steel F22 Flanges for Severe Service Applications

Alloy Steel F22 Flanges are manufactured from chromium-molybdenum alloy steel containing approximately 2.25% chromium and 1% molybdenum. This alloy composition delivers enhanced tensile strength, creep resistance, and oxidation resistance at elevated temperatures. As a result, Alloy Steel ASTM A182 F22 Flanges are widely specified in piping systems exposed to sustained heat and pressure where carbon steel or lower alloy grades may not perform reliably.

ASTM A182 F22 Flanges and International Material Standards

Produced in accordance with ASTM A182 and ASME specifications, ASTM A182 F22 Flanges are recognized across major international engineering codes. Comparable grades include EN 10222 10CrMo9-10, DIN 10CrMo9-10, and ISO-aligned pressure equipment materials. This alignment with global standards enables EPC contractors to maintain consistency across multi-country projects while meeting local regulatory and inspection requirements.

Manufacturing Discipline Behind Alloy Steel ASTM A182 F22 Flanges

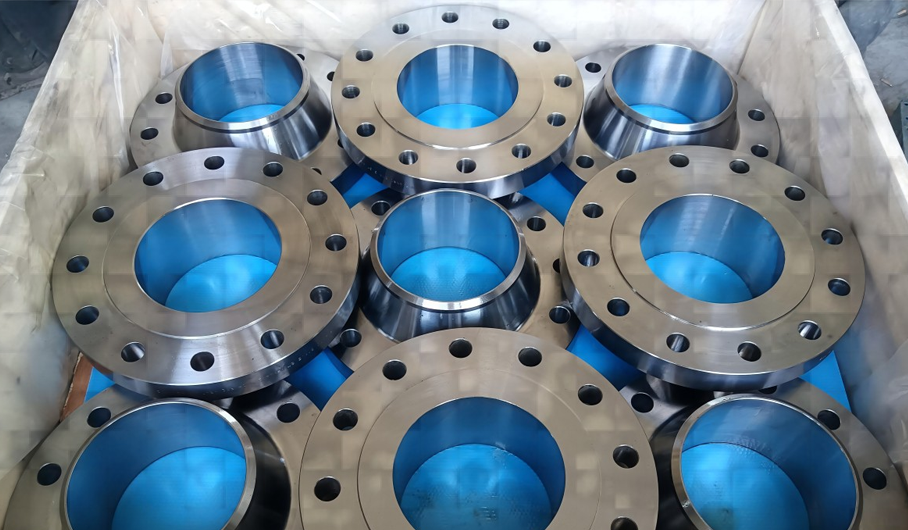

The performance integrity of Alloy Steel F22 Flanges begins with controlled forging practices that ensure uniform grain flow and structural strength. Carefully designed heat treatment cycles further enhance mechanical properties such as toughness, hardness, and resistance to thermal fatigue. These disciplined manufacturing processes ensure consistency across production batches, supporting large-scale international supply programs.

Quality Control Systems Designed for Global Projects

Each Alloy Steel ASTM A182 F22 Flange is subjected to comprehensive quality control protocols. These include chemical composition testing, tensile and impact testing, hardness verification, and non-destructive testing such as ultrasonic inspection. Complete traceability through heat numbers, Mill Test Certificates, and optional third-party inspection ensures full compliance with ASTM, ASME, EN, and DIN standards, providing confidence for export-oriented EPC projects.

Performance Advantages in High-Temperature and High-Pressure Service

ASTM A182 F22 Flanges are engineered to maintain dimensional stability and mechanical strength under continuous thermal and pressure cycling. The chromium-molybdenum alloy structure minimizes scaling, oxidation, and deformation, making Alloy Steel F22 Flanges suitable for superheated steam lines, pressure vessels, and critical process piping where long-term reliability is essential.

Industries That Rely on ASTM A182 F22 Flanges

Alloy Steel ASTM A182 F22 Flanges are extensively used across oil and gas refineries, petrochemical complexes, thermal and combined-cycle power plants, fertilizer units, and chemical processing facilities. EPC contractors frequently specify F22 flanges for boilers, heat exchangers, and high-temperature piping networks due to their consistent performance and international acceptance.

Global and Regional Project Demand

Demand for Alloy Steel F22 Flanges remains strong in regions investing heavily in energy and industrial infrastructure, including the Middle East, India, Southeast Asia, Europe, and Africa. Their compatibility with international standards makes ASTM A182 F22 flanges particularly suitable for cross-border projects that require unified specifications and long-term operational assurance.

Export-Ready Supply Chain and Logistics Capability

As a globally recognized steel manufacturing brand, export readiness is integrated into every stage of production. Alloy Steel F22 Flanges are supplied with durable, seaworthy packaging, clear permanent marking, and comprehensive documentation to support international shipping and customs clearance. Efficient logistics coordination ensures timely delivery to fabrication yards, EPC sites, and end-user facilities worldwide.

Dimensional Range and EPC-Oriented Customization

ASTM A182 F22 Flanges are manufactured across a broad range of sizes, pressure classes, and facing types in accordance with ASME B16.5, ASME B16.47, and relevant EN or ISO dimensional standards. Custom machining, special drilling patterns, and project-specific tolerances are available to support complex EPC requirements and retrofit applications.

Lifecycle Value and Operational Efficiency

While Alloy Steel ASTM A182 F22 Flanges may represent a higher initial investment compared to lower alloy grades, their extended service life and reduced maintenance requirements deliver superior lifecycle value. Improved resistance to thermal fatigue and pressure-related degradation helps minimize downtime and enhances overall plant efficiency.

Commitment to Consistency, Innovation, and Global Trust

In today’s interconnected industrial supply environment, long-term partnerships are built on consistent quality, technical expertise, and forward-looking manufacturing practices. Continuous investment in process optimization, metallurgical control, and quality systems ensures that Alloy Steel F22 Flanges remain aligned with evolving international standards and future project demands.

As global industries pursue higher efficiency, greater safety, and longer asset life, ASTM A182 F22 Flanges remain a reliable foundation for high-temperature piping systems. Supported by manufacturing excellence, rigorous quality control, and a truly global supply capability, ASTM A182 F22 flanges deliver lasting confidence, innovation, and long-term value for international industrial projects.

Contact Details:-

Address- 10, Floor-2, 18, Vijay Apartment, Khetwadi 12th Lane, Girgaon, Mumbai-400004.

Mail- [email protected]

Number- +91-91725-59933

Site- https://www.mfpind.com/